TECHNICLEAN (MACHINE)

- Model TEACHNICLEAN – MACHINE

- From TECHNICLEAN

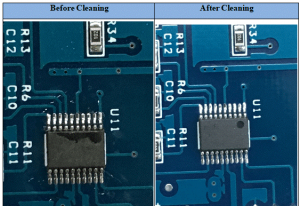

Audio-Technica’s TechniClean is a state-of-the-art cleaner that adopts special adhesive rollers across the entire product line. The rollers’ adhesive strength can be used to effectively remove dust, particles, and other debris on as well as to remove static electricity from resin boards, glass, film sheets, metal plates, and more. TechniClean can remove nearly all small particles.

FEATURE

Wide range of conveyers

Select a conveyer, mini conveyer, round belt conveyer, flat belt conveyer, or pully conveyor (options) depending on the material to be cleaned.Cleaning operations

PLC control facilitates reversible, continuous, automatic one-way, and automatic two-way cleaning operations.Choices of material working widths

The working width of the material to be cleaned can vary from 30 to 1500mm (up to 600mm for silicone rubber) and can be selected per material. We can manufacture a specially sized adhesive roller with our adhesive rubber as well. * Manufacturing is performed under certain specified conditions

BUTYL SYNTHETIC RUBBER |

|

|

|